Choosing the right option for your business is something that is uncompromisable at any cost and should be chosen with proper planning and effective analysis.

Just like product packaging, you should know the benefits of shrink film or product packaging. You can also outsource the Shrink wrapping Service.

What is it?

Shrink film is an efficient packaging solution for many types of products, offering valuable advantages like flexibility, durability, and environmentally friendliness.

Though choosing the right shrink film and machinery can be confusing, it should be done effectively to ensure everything is done on a proper basis.

The following details are required to focus on the right shrink film and shrink film machine –

- Proper gauge,

- Size, tunnel length,

- packaging purpose, storage.

Our Way Of Working.

With the help of experts and different techniques, we produce what is best, and reliable.

We work with proper consideration that our innovation would not lead to any environmental burdens. We work with a focus, to eliminate bad effects on the planet. We have paved the way for more growth and fewer effects on planets by uplifting us in a way to compete with challenges and produce the best.

To get satisfying results from shrink wrapping solution the shrink film must be in the proper specification for the shrink packaging machine used. Also, the final result of the products depends on the machine used.

- The shrinkage ratio of film used

- Applied hear on it

- Heat application units.

These all result in direct or inverse proportion to each other. In all these processes, the quality of shrink film has great cruciality as a shrinking machine.

If you are having a good quality, well-performing shrink tunnel, it is purely gonna not to risk you at any point in time.

Especially when trying to cover up mistakes of machine equipment with high prices, shrink film will lead to an increase in total packaging cost.

To avoid this shrink packaging machines should be brought once and attention is properly paid to the potential that it functions properly at maximum.

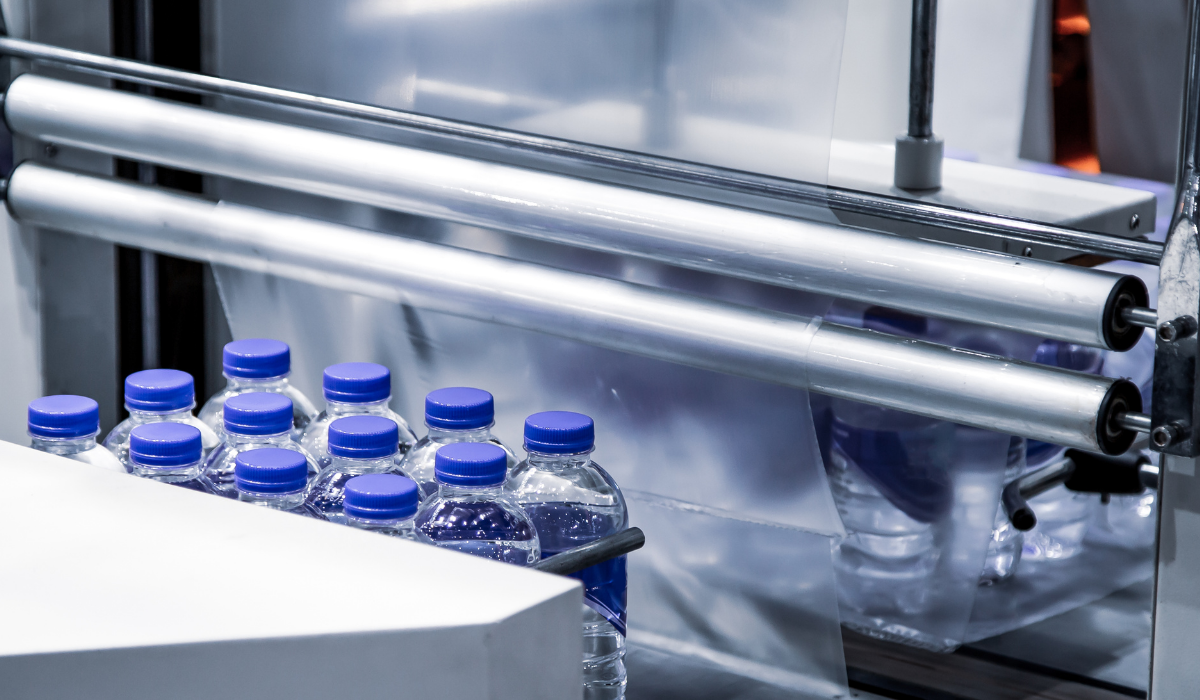

Shrink Packaging Process

The shrink packaging process is crucial in various steps. Shrink film runs through a special mechanism that is scaling machines, opening two layers of the film. The product and the film run at parallel speeds with each other placing all productions in the folding center. Once the film covers the product, the sealers come into action to seal.

Types of sealers

L sealer for films in which all 3 sides need to seal, the first seal is dared manually. Their remaining sides need to be sealed. In L sealing this is done with the help of an L-shaped jaw.

Continuous sealers, On the side act as sewing machines that seeds that shrink film that runs through in production flow have two vertical jaw options. The right vertical sealers depend on a few variables such as the dimensions of the product, and production capacity.

Efficiency in shrink packaging

Shrink packaging machine technology has come a long way in a short time.

Servo motor technology has become standard technology. Software and hardware integrations and the advanced communications between them have set the ground for new advancements. The introduction of mechatronics made many things possible for new ideas to be put into practice at the speed of light. New functions can be added not only to shrink the process itself but integration such as – brocade readers. Weights Labellers.

Machines can be shown as entry-level examples of shrink packaging machines.

These machines have been temporary solutions for small and medium-sized companies for many years.

However, these entry-level shrink packaging machines will not be able to meet the expectations of an industrial-level high production capacity. An operator can’t feed an automatic machine with 100% efficiency.

Even in the best conditions, it is necessary to calculate a feed-based loss of 20% in hand-fed automatic machines.

Shrink packaging has a great place within the context of ” flexible packaging “. It is used in a wide range of industries like –

- food

- Automobile

- Textiles

- Stationery packaging.

Shrink packaging is the last and most vital phase of the production process and has an effect. Choosing the right shrink packaging machine and packaging cost – Time, quantity, labour .

Common problems in the packaging operation

- Labour tendency

- Time loss

- Employment load

- Irregular management

- Damage to brand

- Competitions

- Burden

- Unhealthy process flow

- Physical field losses